Sep. 08, 2023

Automobiles & Motorcycles

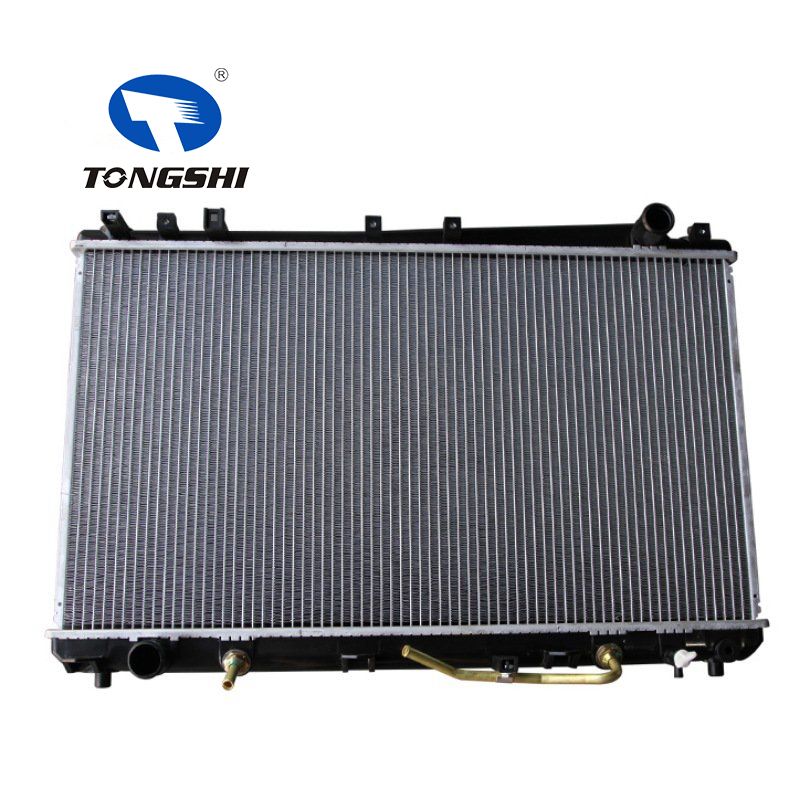

The radiator is one of the main working components in the engine water cooling system. After the radiator is used for a long time, the core tube will be blocked and the coolant will leak out, which will cause the engine temperature to rise and affect the normal operation of the engine. Therefore, we must learn how to check and troubleshoot its faults.

Radiator core pipe blocked

When the engine speed is medium and low, the coolant temperature is normal. After high speed, the coolant temperature rises sharply. At this time, you should focus on checking whether the radiator is blocked. The reason why the radiator is clogged is that in addition to the impurities contained in the original coolant, mixing different brands of coolants will produce white crystals, which can easily block the narrow water channels in the radiator, causing the circulation of the cooling system to be blocked, causing the engine coolant temperature to rise too high. high.

1 Radiator blockage fault inspection

a. Detect the temperature difference between the inlet and outlet pipes of the engine radiator: Use an infrared thermometer to detect whether the engine radiator cooling fluid channel is blocked. The temperature of the engine radiator outlet is the engine coolant temperature, and the return pipe is the coolant temperature after cooling, which should be about 30°C lower than the temperature of the water outlet. If the temperature of the return pipe is too low, it means that the radiator is blocked and the coolant circulation stops.

b. Observe the flow of coolant in the overflow pipe: After the heat engine reaches the temperature at which the thermostat opens, one person steps on the accelerator pedal, and the other person observes the flow of coolant in the overflow pipe. If a large amount of radiator coolant flows out of the overflow pipe during rapid acceleration, it indicates that the radiator is seriously clogged, resulting in increased flow resistance of the coolant and inability to circulate in time. A clogged radiator coolant passage will cause the engine operating temperature to be too high, and the radiator must be cleaned.

c. If there is space for inspection: You can use an infrared thermometer to detect the surface temperature of the radiator. If the temperature in the middle of the radiator is high and the temperature around it is low, it means that the water pipe in the lower part of the radiator is blocked and the radiator should be cleaned.

d. Early wear of the water pump wheel: After the engine reaches normal operating temperature, touch the upper and lower water pipes of the radiator with your hands. If the temperature of the upper water pipe of the radiator is low, it means that the thermostat does not open. The thermostat should be replaced; the temperature of the lower water pipe of the radiator is low. If it is low, it means that the water pipe at the bottom of the radiator is blocked, or the plastic impeller of the water pump is damaged (modern engines mostly use plastic water pump impellers, and no abnormal sound can be heard after the water pump impeller is worn). Use an infrared thermometer to detect the radiator. If the temperature in the middle of the radiator is high and the temperature around it is low, it means that the water pipe at the bottom of the car radiator is clogged and the radiator should be cleaned. If the temperature is uniform in the middle and around the radiator, it means that the water pipe in the lower part of the radiator is not blocked, and the fault lies in the water pump wheel. The worn water pump wheel should be replaced in time. Many models require that when replacing the timing belt, in addition to replacing the tensioner pulley, the water pump pulley must also be replaced.

e. Chemical reactions will corrode the radiator water pipes, causing the water pipes on the radiator to be too soft. The electrochemical reaction is caused by the mutual replacement of antifreeze and water pipe materials in the coolant. If the boundary between the coolant and the pipe forms a ground, a path from the coolant to the ground may be formed, which will aggravate the corrosion of the hose. Use your fingers to slide on the hose. If you find which part is softer, it means that it is corroded.

Connect the negative terminal of the digital multimeter to ground and place the positive terminal in the coolant. If the voltage is greater than 0.3 V, check the ground connection. If the grounding is not good, the grounding circuit will use the coolant as a grounding channel, thereby accelerating corrosion of the radiator water pipe.

The water pipe on the radiator must maintain a certain hardness. The water pipe that is too soft will be sucked flat at high speed, resulting in increased water flow resistance and blocked coolant circulation.

Suggested reading:2 Troubleshooting methods

Chemical removal: To prepare the cleaning solution, the first is to add 750 g of caustic soda (caustic soda) to 10 L of water, and then add 250 g of kerosene; the second is to add 700 to 1000 g of caustic soda to 10 L of water, and then add 150 g of kerosene. The former cleaning fluid is more corrosive and is used to clean cooling systems with heavy scale. The latter cleaning fluid is less corrosive and can be used to clean cooling systems with lighter scale.

Before cleaning, drain the original cooling water, remove the thermostat, and then add cleaning fluid. Start the engine and run it at a medium speed for 5-10 minutes, and stop for 12 hours (or work for one shift). Restart the engine and make the speed increase and decrease. Use the impact of water to suspend scale and other sediments. After running for 10 to 15 minutes, stop running and release the cleaning fluid while it is hot. After the engine is slightly cold, add clean water and run it at medium speed for 4 to 5 minutes to circulate the water. Repeat this 2 to 3 times and check the discharged water at the same time until the discharged water is clean. Finally, reinstall the thermostat and add enough clean cooling water.

Radiator leaking

1 Check for radiator leakage

The leaking parts are usually the four corners and outer core.

a. Irrigation method: During inspection, pour hot water into the water tank, and traces of water leakage can be observed in the damaged parts. This method is convenient to check, but it is not easy to find the internal leakage of the tiny crack.

b. Air pressure method: when checking, it can be carried out with an air compressor or an air pump, and it can be done at the grassroots maintenance points. Try to connect the radiator to the upper and lower sinks (or connect the radiator to a special sealing cover), immerse it in water, press air into the radiator through the hose, and observe whether there are bubbles escaping from the Passenger Car Radiator. The air pressure pressed into the radiator should be 1 to 2 atmospheres, and the time should be no less than 1 minute. After checking one side, turn the radiator over to check the other side.

2. Troubleshooting of radiator leakage

Depending on the location and degree of leakage of the radiator core tube, different methods can be used to repair it, and the radiator core tube should be replaced if necessary. If the number of leaking cooling core tubes does not exceed about 10% of the total number of cooling core tubes, it can be repaired by blocking the core tubes. If the number of leaking heat sink core tubes exceeds 15%, this method cannot be used to avoid reducing the cooling effect of the cooling system. The welding repair method can be used to solder individual leaking parts of the heat sink core tube.

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )