Jan. 16, 2024

Mechanical Parts & Fabrication Services

In the dynamic realm of oil and gas exploration, the terms Workover Rig and Drilling Rig are frequently encountered, each playing a crucial role in the extraction process. Understanding the distinctions between these two types of rigs is essential for industry professionals and enthusiasts alike.

A Workover Rig often referred to as a completion rig, is primarily employed for maintenance and enhancement of existing wells. These rigs are brought into action after the initial drilling phase has concluded. Their main tasks include remedial operations, well interventions, and the installation of various downhole equipment. Workover Rigs play a pivotal role in rejuvenating declining wells, optimizing production, and ensuring the longevity of the overall reservoir.

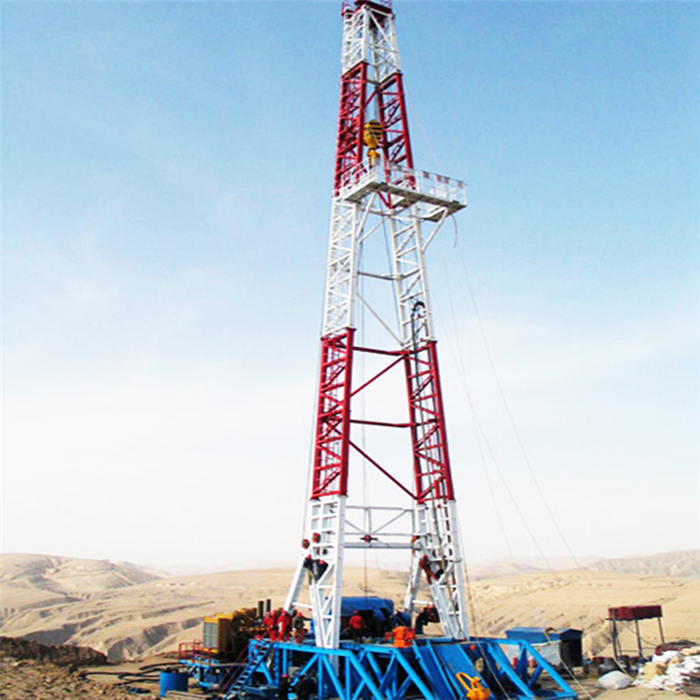

On the other hand, a Oil Drilling Rig is utilized during the initial phase of oil and gas exploration. Its primary function is to create a wellbore by drilling into the subsurface layers of the Earth. Drilling Rigs are equipped with specialized tools and machinery to penetrate the earth's crust, allowing for the extraction of valuable hydrocarbons. These rigs are instrumental in the discovery of new reservoirs and the commencement of production activities.

The disparity between Workover Rigs and Drilling Rigs lies in their respective purposes and the stages of the oil and gas extraction process at which they are employed. While Workover Rigs focus on maintaining and optimizing existing wells, Drilling Rigs are integral to the exploration and initiation of new wells.

In terms of design and functionality, Workover Rigs are often more compact and mobile compared to Drilling Rigs. The former is designed for quick deployment and efficient operation on existing well sites. Drilling Rigs, conversely, are engineered for the complex task of creating a wellbore, requiring more extensive equipment and infrastructure.

It is crucial for industry professionals to grasp the nuanced differences between Workover Rigs and Drilling Rigs to streamline operational efficiency. Misidentifying or misusing these rigs can result in costly mistakes and delays in the production process.

In conclusion, the utilization of Workover Rigs and Drilling Rigs in the oil and gas industry hinges on the specific needs of each operational phase. Workover Rigs contribute to the optimization and maintenance of existing wells, ensuring sustained production. In contrast, Drilling Rigs play a pivotal role in the exploration and initiation of new wells, paving the way for the discovery of untapped hydrocarbon reserves. By comprehending the unique functions and characteristics of these rigs, industry professionals can navigate the complex landscape of oil and gas extraction with precision and efficiency.

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )