Jun. 19, 2024

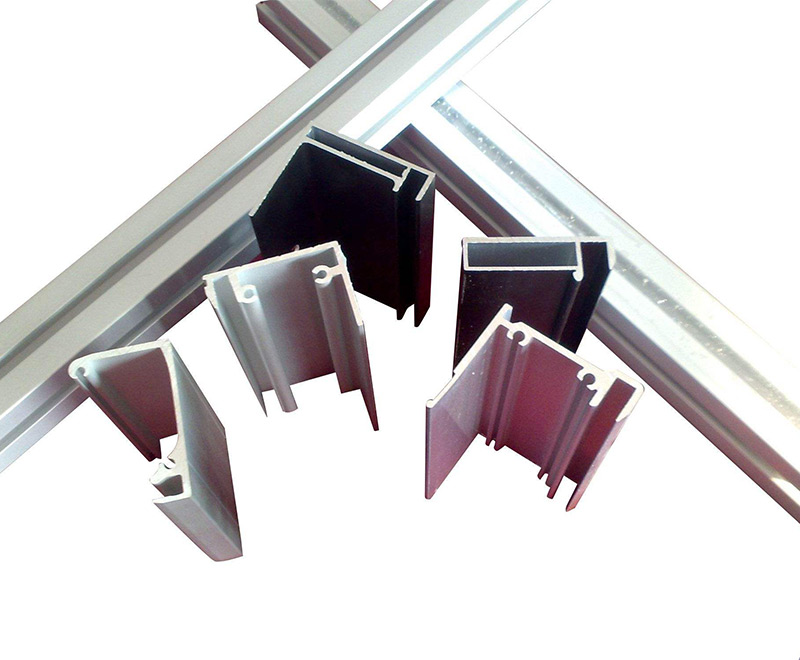

Aluminum alloy building profiles are a kind of aluminum alloy hot extruded profiles used to process aluminum alloy doors, windows, glass curtain walls and decoration. They are light, beautiful and durable, and are widely used in various construction and decoration industries. Today we mainly introduce several simple identification methods of anodized colored profiles.

Identity check

Whether the aluminum profile and packaging are marked with the product standard code and production license number, etc.

Surface Quality

In addition to being clean and not allowing defects such as cracks, peeling, corrosion, and bubbles, the surface of aluminum profiles is also not allowed to have defects such as corrosion spots, electric burns, black spots, and peeling off oxide films.

Oxide film thickness

The oxide film of aluminum profiles is formed during anodization and has a protective and decorative effect. It can be detected with an eddy current thickness gauge.

Sealing quality

There are many gaps left on the surface of aluminum profiles after anodization. If they are not sealed or are not sealed well, the corrosion resistance of the aluminum profiles will be reduced. Commonly used methods for sealing quality inspection include acid leaching method, admittance method and phosphobutyric acid method. The acid leaching method is generally used in on-site inspections, that is, scrub the surface of the custom aluminum profile with acetone to remove oil and dust, drop 50% nitric acid by volume onto the surface and scrub gently, wash off the nitric acid with clean water after 1 minute, and then wipe Dry, drop a drop of medical violet onto the surface. After 1 minute, wipe off the violet and clean the surface thoroughly. Carefully observe the traces left. Aluminum profiles with poor sealing will leave obvious traces. The heavier the traces, the better the sealing quality. The worse.

Corrosion resistance

This indicator mainly affects the life of the aluminum profile. The corrosion resistance test includes the copper accelerated acetate salt spray test and the alkali dropping test. Here we introduce the alkali dropping test, that is, at 35℃±1℃, add about 10mg, 100g/L NaOH Drop the solution onto the surface of the aluminum profile, visually observe the droplets until corrosion bubbling occurs, and calculate the penetration time of the oxide film. This test is easy to conduct preliminary judgment outdoors in summer. To ensure the accuracy of the test, it must be done in the laboratory. carried out under the strict conditions of the laboratory.

Generally speaking, to identify the advantages and disadvantages of aluminum profile doors and windows, there are six main aspects that you can refer to in terms of materials:

1. Thickness

There are two types of aluminum alloy sliding doors, 70 series and 90 series. For aluminum alloy sliding doors in residential buildings, 70 series can be used. The series number indicates the thickness of the door frame in millimeters of construction dimensions. There are four types of aluminum alloy sliding windows: 55 series, 60 series, 70 series and 90 series. The series selection should be based on the size of the window opening and the local wind pressure value. Aluminum alloy sliding windows used for enclosed balconies should be no smaller than 70 series.

2. Strength

The tensile strength should reach 157 Newtons per square millimeter and the yield strength should reach 108 Newtons per square millimeter. When purchasing, you can bend the profile appropriately with your hands, and it should return to its original shape after letting go.

Three colors

The color of the same aluminum alloy profile should be consistent. If the color difference is obvious, it is not suitable to purchase.

4. Flatness

Check the surface of the aluminum alloy profile. There should be no dents or bulges.

5. Glossiness

For aluminum alloy doors and windows, avoid purchasing profiles with open bubbles (white spots) and ash (black spots) on the surface, as well as obvious defects such as cracks, burrs, and peeling.

6. Degree of oxidation

The thickness of the oxide film should reach 10 microns. When purchasing, you can lightly scratch the surface of the profile to see if the oxide film on the surface can be wiped off.

Previous: Properties and advantages of using metals and alloys

Next: Chromium

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )