Aug. 07, 2023

Mechanical Parts & Fabrication Services

In the realm of engineering and manufacturing, precision and reliability are paramount. Amidst the complex machinery and intricate systems that power our modern world, a seemingly unassuming component known as the O-ring plays a pivotal role. These unobtrusive yet vital rings have found their way into a diverse range of applications, ensuring seamless functionality and preventing leaks in various industries. This article delves into the multifaceted uses and significance of O-rings in today's technologically advanced landscape.

The Basics of an O-Ring

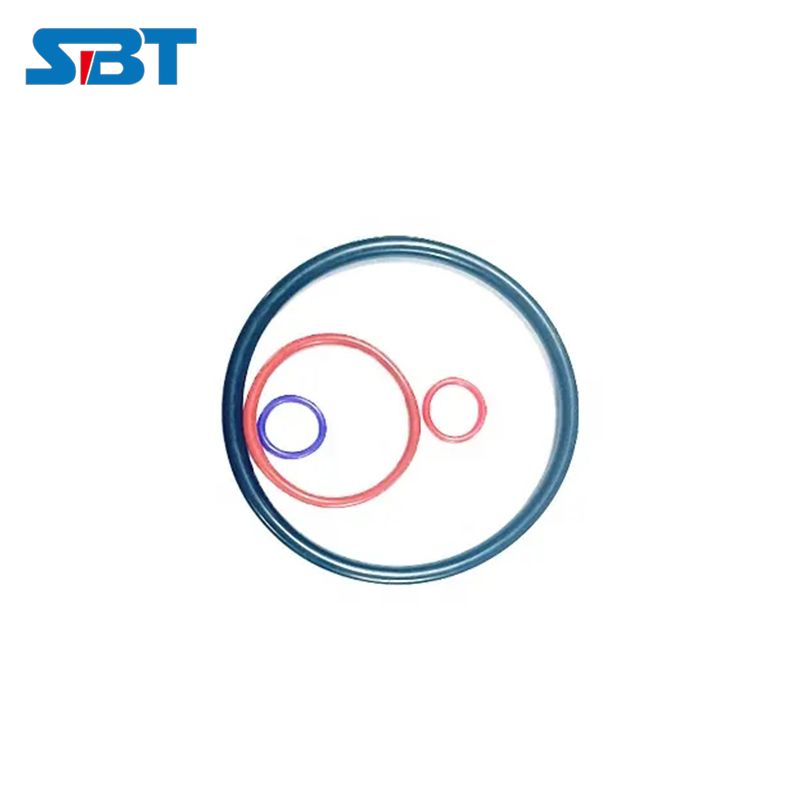

An O-ring, as its name suggests, is a circular rubber or elastomeric ring with a cross-sectional shape resembling the letter "O." It is designed to fit snugly into a groove between two mating surfaces, creating a reliable seal that prevents the escape of fluids or gases. This simple yet ingenious design has catapulted the O-ring into an indispensable component across numerous sectors.

Industrial Applications

Hydraulic Systems: O-rings are integral to hydraulic systems, which transmit power using pressurized fluids. These rings prevent fluid leakage between components, such as cylinders and valves, ensuring optimal system performance.

Pneumatics: In pneumatic systems that use compressed air to transmit power, O-rings provide airtight seals that prevent loss of pressure, enhancing efficiency and reliability.

Automotive Industry: O-rings are prevalent in engines, transmissions, and fuel systems, helping to maintain the integrity of various fluids and ensuring smooth operation.

Aerospace: The extreme conditions of space and high-altitude flight demand impeccable sealing solutions. O-rings are vital components in aerospace applications, safeguarding against the escape of fluids and maintaining cabin pressure.

Medical Devices: custom O-rings play a crucial role in medical devices, from syringes to diagnostic equipment, where leak prevention is paramount to patient safety and accuracy.

Consumer Goods

Plumbing: In residential and commercial plumbing systems, O-rings are used to create watertight seals in faucets, valves, and pipe connections, preventing leaks and water wastage.

Appliances: From washing machines to coffee makers, O-rings help maintain airtight seals in water and air lines, contributing to the efficiency and longevity of household appliances.

Electronics: O-rings find their place in electronic devices, creating seals in connectors and enclosures to protect delicate components from moisture and contaminants.

Challenges and Innovations

While O-rings offer exceptional sealing capabilities, certain challenges have driven innovations in their design and materials. High-temperature environments, corrosive fluids, and extreme pressures have prompted the development of specialized O-rings crafted from materials like fluorocarbon, silicone, and nitrile rubber. These adaptations ensure that O-rings maintain their integrity and performance under demanding conditions, expanding their applications to even more industries.

Conclusion

In a world driven by precision, efficiency, and reliability, the humble O-ring stands as a testament to the power of simplicity. From hydraulic systems that propel heavy machinery to the delicate internals of medical devices, these unassuming rings ensure that fluids and gases remain where they belong. The versatility and importance of O-rings are underscored by their pervasive presence in virtually every sector, contributing to the smooth operation of industries that shape our daily lives. As technology advances and new challenges arise, the O-ring continues to evolve, demonstrating its resilience and adaptability as a crucial component in the ever-evolving landscape of engineering and innovation.

Previous: Are Kubota diesel engines good?

Next: What is the difference between a slurry pump and a water pump?

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )