Jan. 04, 2024

Tools

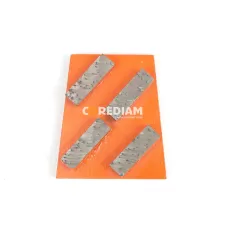

Diamond grinding shoes are essential tools for professionals engaged in concrete grinding and polishing applications. These shoes, embedded with industrial-grade diamonds, are designed for durability and efficiency in surface preparation. Whether you're a seasoned contractor or a DIY enthusiast, here's a comprehensive guide to help you make an informed decision when buying diamond grinding shoes:

1. Understanding Diamond Grit:

Diamond grit determines the aggressiveness and coarseness of the grinding process. Lower grit numbers (e.g., 16-30) are more aggressive and suitable for coarse grinding, while higher grit numbers (e.g., 100-400) are ideal for finer polishing. Consider the specific needs of your project when selecting diamond grit.

2. Bond Types:

Different bonds are used to hold the diamonds in place. Soft bonds are designed for hard concrete, while hard bonds are suitable for softer concrete. Medium bonds provide a balance between the two. Assess the hardness of the concrete you'll be working on to choose the appropriate bond type.

3. Segment Configuration:

The arrangement of diamond segments on the grinding shoe affects the tool's performance. Single-row segments are more aggressive, making them suitable for initial grinding, while double-row or turbo segments offer a smoother finish and are preferable for polishing. Select the segment configuration based on the level of aggressiveness required for your project.

4. Shoe Shape and Size:

Diamond Grinding shoes come in various shapes, such as round, rectangular, or arrow-shaped. The shape affects the tool's maneuverability and the finish it achieves. Additionally, consider the size of the shoe, ensuring compatibility with your grinder or grinding machine.

5. Application Compatibility:

Different diamond grinding shoes are designed for specific applications, including coating removal, surface preparation, or polishing. Ensure that the shoes you choose are suitable for the tasks you need to accomplish. Some shoes may be versatile for multiple applications.

6. Durability and Lifespan:

Evaluate the quality of the diamond and the overall construction of the grinding shoe. Premium-quality diamonds and robust bonding materials contribute to longer tool life. Investing in durable grinding shoes can lead to cost savings over time.

7. Wet or Dry Grinding:

Determine whether your project requires wet or dry grinding. Some grinding shoes are specifically designed for wet applications, providing better dust control and extended diamond life. Others are suitable for dry grinding, offering convenience in certain situations.

8. Brand Reputation:

Choose diamond grinding shoes from reputable brands with a history of producing high-quality tools. Read customer reviews and seek recommendations from professionals in the industry to ensure reliability and performance.

9. Price vs. Quality:

While price is a consideration, prioritize quality over cost. Cheaper options may compromise on diamond quality and bonding materials, leading to quicker wear and reduced efficiency. Assess the overall value and performance of the grinding shoes.

10. Safety Considerations:

Prioritize safety by opting for grinding shoes equipped with features such as reinforced cores, enhancing both strength and stability. Adhere strictly to manufacturer guidelines, and always wear the necessary protective gear during tool usage.

By considering these factors, you can confidently select the right diamond grinding shoes for your specific project. Whether you're tackling a large-scale concrete polishing job or a smaller DIY project, choosing the appropriate grinding shoes ensures optimal performance and efficient results.

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )