Jun. 13, 2023

Mechanical Parts & Fabrication Services

Centrifugal pumps play a crucial role in numerous industries by efficiently moving fluids from one place to another. They harness the principles of fluid dynamics to generate kinetic energy and facilitate the transportation of liquids. In this article, we will explore the fundamentals of centrifugal pumps, their applications, benefits, factors to consider when choosing them, and maintenance tips for optimal performance.

Understanding Centrifugal Pumps

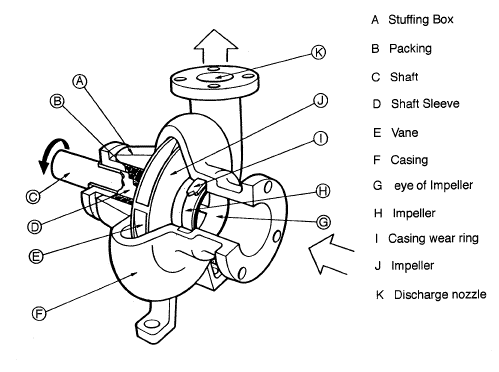

Centrifugal pumps are dynamic machines that use rotational energy to transfer fluids. They consist of several key components, including an impeller, a casing, and a shaft. These pumps are commonly used in various industries such as oil and gas, water treatment, chemical processing, and HVAC systems.

Centrifugal pumps operate based on the principle of centrifugal force. The pump's impeller rotates, creating a low-pressure area at the center. This low pressure draws fluid into the pump through the suction pipe. As the impeller continues to rotate, the fluid is accelerated and forced towards the pump's outer edge. This acceleration increases the fluid's kinetic energy, causing it to move through the pump's casing and out through the discharge pipe.

Centrifugal pumps find extensive use in various applications, including:

Water Supply: Centrifugal pumps are commonly employed for water supply in residential, commercial, and industrial settings. They are used to transport water from wells, rivers, or reservoirs to different locations.

Chemical Processing: Centrifugal pumps are essential in the chemical industry for transferring corrosive and hazardous liquids. They are designed to handle a wide range of chemicals and maintain the integrity of the fluid being transported.

Oil and Gas Industry: Centrifugal pumps are utilized for various tasks in the oil and gas sector, such as crude oil transfer, pipeline boosting, and offshore platform operations.

Heating, Ventilation, and Air Conditioning (HVAC): Centrifugal pumps are integral to HVAC systems, where they circulate chilled water or hot water for heating, cooling, and ventilation.

Wastewater Treatment: Centrifugal pumps play a vital role in wastewater treatment plants, where they move wastewater through different treatment processes, including pumping sewage from residential and industrial areas to treatment facilities.

Efficiency: Centrifugal pumps are known for their high efficiency in transferring fluids. They can handle large volumes of liquids with relatively low energy consumption, making them cost-effective in the long run.

Compact Design: Centrifugal pumps have a compact design, allowing for easy installation in various settings, including tight spaces.

Low Maintenance: These pumps have fewer moving parts compared to other pump types, resulting in lower maintenance requirements and reduced downtime.

Versatility: Centrifugal pumps can handle a wide range of fluids, including liquids with high viscosity or containing solids. They can adapt to different applications by selecting appropriate materials for construction.

When selecting centrifugal pumps for specific applications, several factors should be considered:

1. Flow Rate and Pressure Requirements

Determine the required flow rate and pressure to ensure the selected pump can meet the system's demands effectively.

2. Fluid Properties

Consider the characteristics of the fluid being pumped, such as viscosity, temperature, corrosiveness, and presence of solids. Choose a pump that is compatible with the fluid's properties to ensure optimal performance and longevity.

3. Pump Efficiency

Evaluate the pump's efficiency to minimize energy consumption and operational costs. Look for pumps with higher efficiency ratings.

4. Construction Materials

Select the appropriate construction materials based on the fluid properties and the environment in which the pump will operate. Materials such as stainless steel, cast iron, or specific alloys may be required to resist corrosion or handle abrasive fluids.

Proper maintenance is essential for the reliable and efficient operation of centrifugal pumps. Consider the following tips:

Regular Inspections: Conduct routine inspections to check for leaks, corrosion, or worn-out components. Address any issues promptly to prevent further damage.

Proper Lubrication: Follow the manufacturer's guidelines for lubrication to reduce friction and extend the lifespan of bearings and other moving parts.

Impeller Clearance: Regularly check and adjust the impeller clearance to maintain optimal pump performance.

Seal Maintenance: Monitor and replace worn-out seals to prevent fluid leaks and maintain proper pressure.

Conclusion

Centrifugal pumps are indispensable in various industries, enabling the efficient movement of fluids for numerous applications. By understanding their working principles, benefits, and factors to consider when selecting them, industries can choose the most suitable centrifugal pumps for their specific needs. Regular maintenance and troubleshooting practices contribute to their longevity and optimal performance, ensuring smooth operations in industrial processes.

Yes, Yongda centrifugal pumps can handle fluids with solids, depending on their design and construction. Specific types of centrifugal pumps, such as solids-handling pumps or slurry pumps, are engineered to handle fluids containing solids efficiently.

Some centrifugal pumps are self-priming, meaning they can automatically remove air from the suction pipe and prime themselves without external assistance. However, not all centrifugal pumps possess this feature, so it is essential to check the pump specifications or consult the manufacturer.

The lifespan of a centrifugal pump can vary depending on factors such as operating conditions, maintenance practices, and the quality of the pump itself. With proper maintenance and care, centrifugal pumps can typically last for several years.

Centrifugal pumps are generally more suitable for low- to medium-viscosity fluids. For high-viscosity fluids, alternative pump types such as positive displacement pumps or gear pumps may be more appropriate.

Simple repairs and maintenance tasks can often be performed by individuals with mechanical knowledge and experience. However, for complex repairs or if you are unsure, it is advisable to seek professional assistance to ensure proper repairs and avoid any potential risks.

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )